Fonte de laser de fibra Cw de módulo único Raycus 1000 W para corte de fibra Rfl-C1000

Descrição

Informação básica

| Modelo Nº. | RFL-C1000 |

| Poder nominal | 1000W |

| Modo de operação | Onda Contínua |

| Peso | 50kg |

| Temperatura de trabalho | 10 - 40ºC |

| Qualidade do Feixe | <1,5 |

| Conector de saída | Qbh (Personalizável) |

| Comprimento de onda central: (Nm) | 1080±5 |

| Frequência máxima de modulação | (kHz): 5 |

| Potência de entrada (V CA ) | 200-240, Monofásico |

| Faixa de ajuste de potência (%) | 10-100 |

| Método de resfriamento | Resfriamento a Água |

| Comprimento da Fibra de Saída (M | 20 (Personalizável) |

| Instabilidade da potência de saída | ±1,5% |

| laser vermelho | Sim |

| Pacote de transporte | Pacote de compensado |

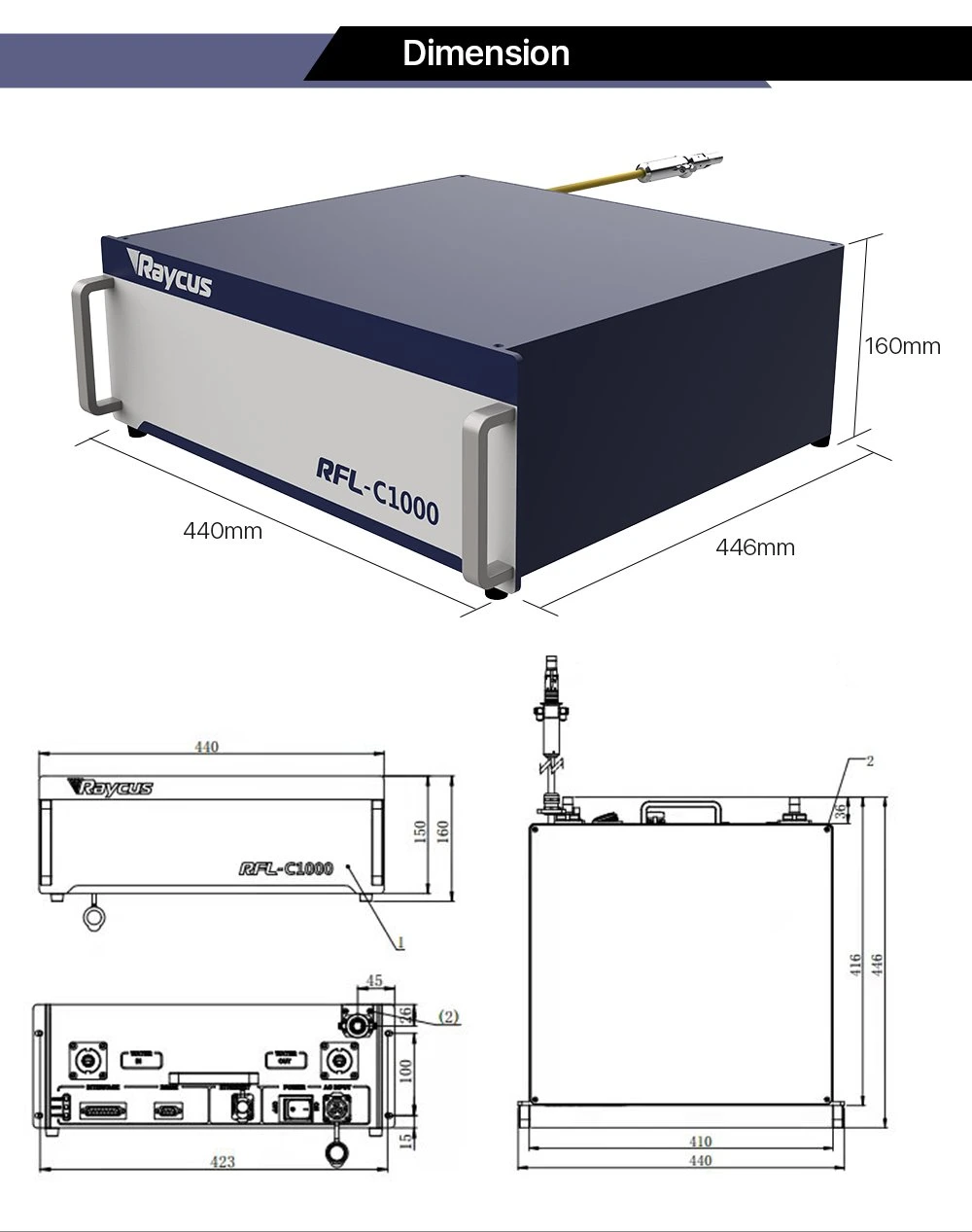

| Especificação | 485× 237× 663 |

| Marca comercial | Raycus |

| Origem | China |

| Código SH | 9013200099 |

| Capacidade de produção | 30 conjuntos/mês |

Descrição do produto

fotos detalhadas

Can mark all metals, rigid plastics, various coated products. It can mark graphics, QR codes, serial number marking, support all fonts, support network communication and secondary development of some special functions.Permanent markerLaser marking is a marking method that uses a high-energy-density laser to locally irradiate the workpiece to vaporize the surface material or undergo a chemical reaction of color change, thereby leaving a permanent mark.2. Marking speed is fastUsing high-speed digital galvanometer, it can carry out assembly line flight marking.3. Maintenance freeBecause the equipment uses advanced fiber lasers, it has high photoelectric conversion efficiency, is easy to use, does notrequire optical adjustment or maintenance, has a compact structure, high system integration, and fewer failures.4. Easy OperationWith the basics of computer use, you can start to operate the machine within 30 minutes of training.5.Easy maintenanceThe whole machine adopts a modular assembly method, and each component can be disassembled independently, which is convenient for fault diagnosis and later maintenance.6. Low failure rateEach component adopts the domestic first-line brand to ensure the stability of the product, and the 48-hour aging test method can be packaged and shipped before leaving the factory.7. Low environmental requirements0.5M², the whole machine is small and compact, and can adapt to harsh processing environments.8. No consumables requiredNo need for any consumables, non-toxic, no environmental pollution, high environmental protection9. Red light positioningUsing red light positioning system, convenient positioning and high positioning accuracy.10. ExtensionsCan be extended with additional functions. Such as circular marking, X Y electric workbench, automatic feeding flight marking, etc.11.Computer programMarking is carried out automatically, marking English, numbers, Chinese characters, graphics, and the printing content can be changed arbitrarily.

Can mark all metals, rigid plastics, various coated products. It can mark graphics, QR codes, serial number marking, support all fonts, support network communication and secondary development of some special functions.Permanent markerLaser marking is a marking method that uses a high-energy-density laser to locally irradiate the workpiece to vaporize the surface material or undergo a chemical reaction of color change, thereby leaving a permanent mark.2. Marking speed is fastUsing high-speed digital galvanometer, it can carry out assembly line flight marking.3. Maintenance freeBecause the equipment uses advanced fiber lasers, it has high photoelectric conversion efficiency, is easy to use, does notrequire optical adjustment or maintenance, has a compact structure, high system integration, and fewer failures.4. Easy OperationWith the basics of computer use, you can start to operate the machine within 30 minutes of training.5.Easy maintenanceThe whole machine adopts a modular assembly method, and each component can be disassembled independently, which is convenient for fault diagnosis and later maintenance.6. Low failure rateEach component adopts the domestic first-line brand to ensure the stability of the product, and the 48-hour aging test method can be packaged and shipped before leaving the factory.7. Low environmental requirements0.5M², the whole machine is small and compact, and can adapt to harsh processing environments.8. No consumables requiredNo need for any consumables, non-toxic, no environmental pollution, high environmental protection9. Red light positioningUsing red light positioning system, convenient positioning and high positioning accuracy.10. ExtensionsCan be extended with additional functions. Such as circular marking, X Y electric workbench, automatic feeding flight marking, etc.11.Computer programMarking is carried out automatically, marking English, numbers, Chinese characters, graphics, and the printing content can be changed arbitrarily.

Nosso contato